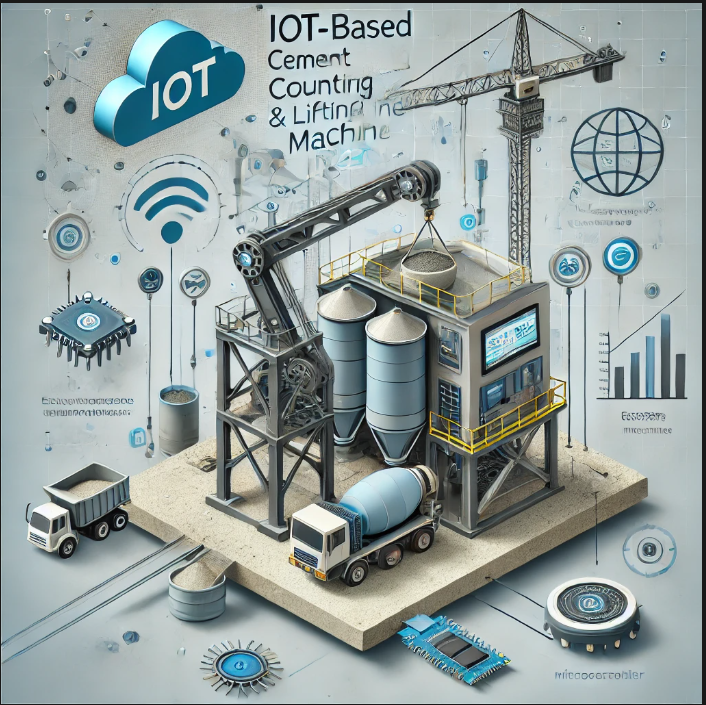

IoT-Based Cement Counting and Lifting Machine

The IoT-Based Cement Counting and Lifting Machine is a proposed solution designed to automate the cement lifting process, accurately track the number of lifting cycles, and differentiate between mixed and unmixed cement. By integrating this system with real-time monitoring through an ESP32 microcontroller, DC motors, and a water sensor, the solution will improve efficiency, reduce labor costs, enhance safety, and provide transparent data on cement usage

System Components and Functions

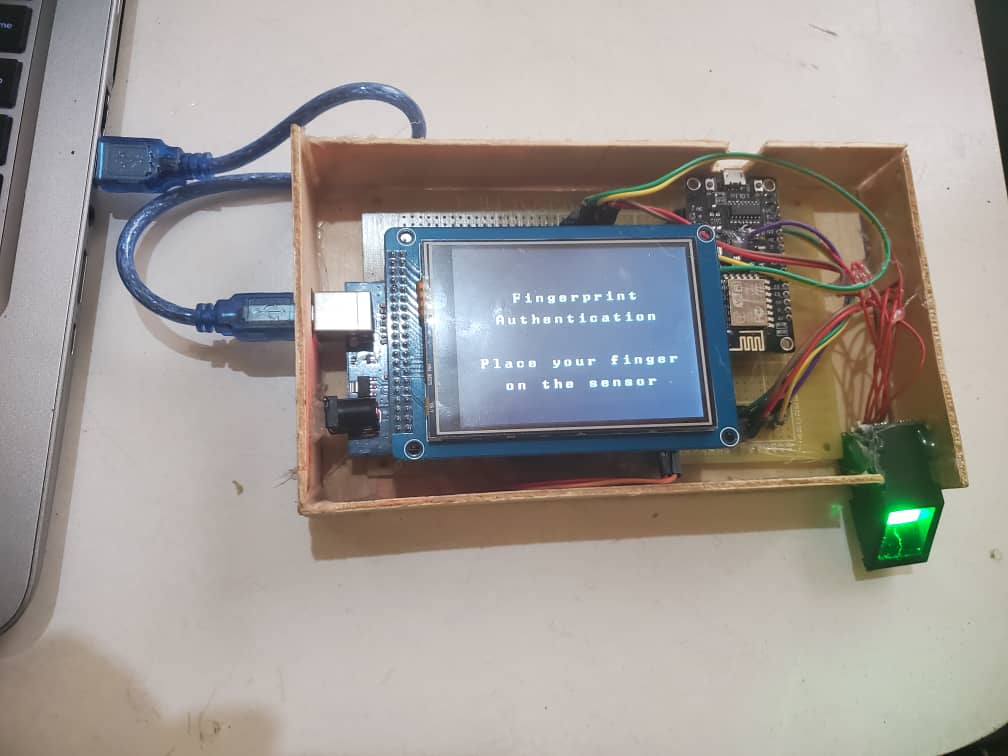

1. Microcontroller (ESP32)

- Role: Acts as the core control unit that manages inputs from sensors, limit switches, and cloud communication while controlling the DC motor.

- Project Context: The ESP32 processes data from the water sensor to detect mixed/unmixed cement, counts lifting cycles, and sends this data to the cloud for real-time monitoring and record-keeping.

2. Supply

- Role: Provides power to the microcontroller, DC motor, and other components.

- Project Context: Ensures reliable operation of the cement lifting machine by supplying consistent power.

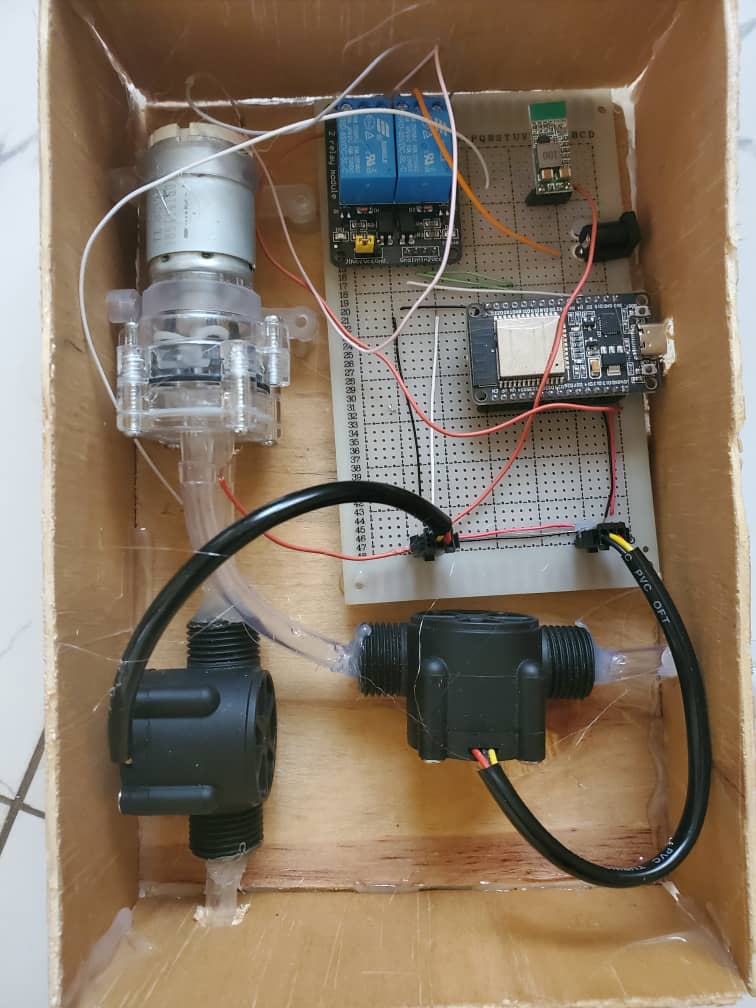

3. DC Motor

- Role: Drives the lifting mechanism for the cement.

- Project Context: Automates the physical lifting of cement bags or containers. The motor's operations are controlled by the microcontroller based on inputs from limit switches and water sensors.

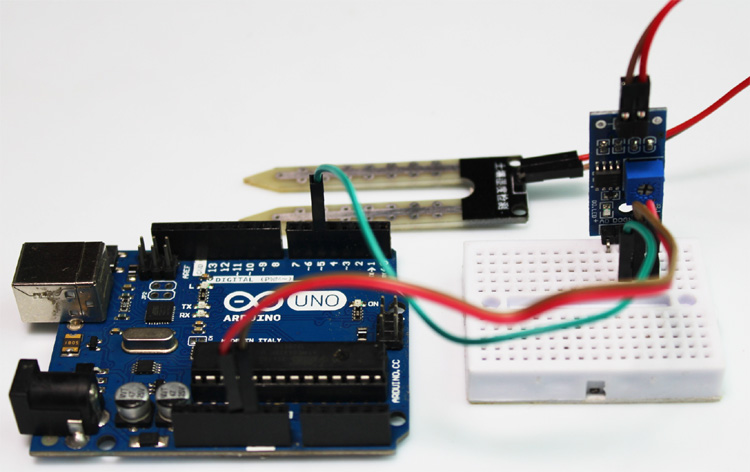

4. Water Sensor

- Role: Detects the presence of water to differentiate between mixed and unmixed cement.

- Project Context: The sensor determines whether the cement is in a mixed state, providing critical data for monitoring.

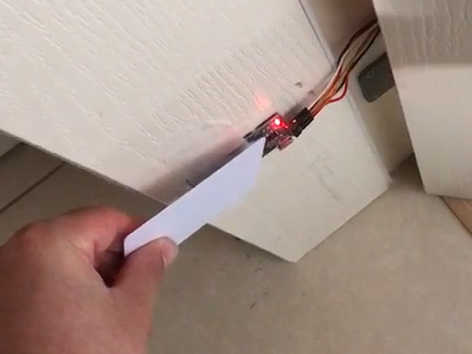

5. Limit Switches (Up and Down)

- Role: Detect the extreme positions of the lifting mechanism.

- Up Limit Switch: Indicates when the mechanism has reached the top position.

- Down Limit Switch: Indicates when the mechanism has reached the bottom position.

- Project Context: Helps the microcontroller count the number of lifting cycles accurately and ensures safe operation by preventing overtravel.

6. Cloud

- Role: Acts as the central hub for storing and accessing data remotely.

- Project Context: Facilitates real-time monitoring of cement lifting cycles, state (mixed or unmixed), and operational status via a dashboard.

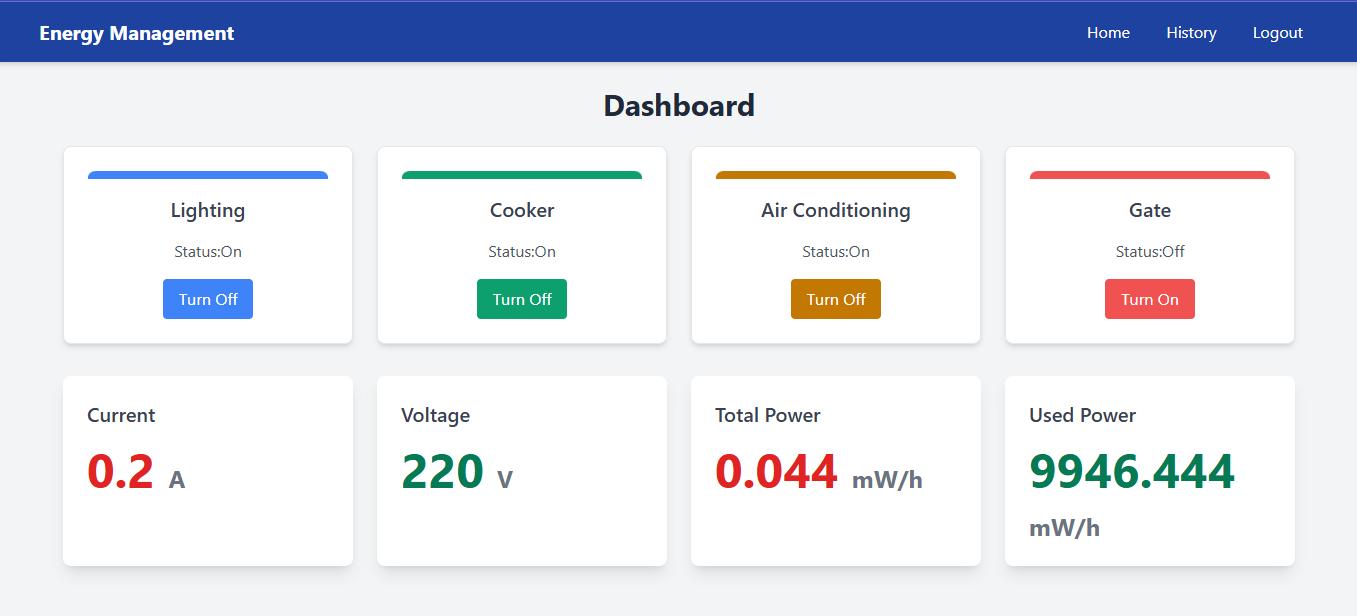

7. Interface (Dashboard)

- Role: Displays data and system status to the user.

- Project Context: Provides a user-friendly interface for monitoring key metrics like lifting cycles, cement state, and operational errors, enhancing transparency.

System Workflow

- Initialization:

- The microcontroller initializes all components, including the motor, sensors, and limit switches.

- Cement Lifting:

- The DC motor activates to lift cement.

- Limit switches track the position of the lifting mechanism (up or down).

- The microcontroller counts each completed lifting cycle.

- Cement State Detection:

- The water sensor determines if the cement is mixed or unmixed during lifting.

- Data Transmission:

- The ESP32 microcontroller sends lifting counts, cement state, and operational data to the cloud.

- Real-Time Monitoring:

- The cloud updates the dashboard in real-time, allowing users to view system status and performance metrics.

- Automation and Safety:

- The system operates autonomously, with limit switches ensuring safe operation by stopping the motor at appropriate positions.

Advantages of the System

- Efficiency: Automates cement lifting, reducing the need for manual labor.

- Safety: Prevents accidents through precise motor control and limit switch mechanisms.

- Transparency: Tracks and displays cement usage, lifting cycles, and cement state.

- Real-Time Monitoring: Provides real-time operational data accessible remotely.

- Cost Reduction: Reduces labor costs through automation.

Components Required

- ESP32

- DC motor

- Limit switch

- Power supply

- Water sensor

- Web App

For More Information

+250783159293

.jpeg)